Tin-based perovskite solar cells with a homogeneous buried interface

Summary

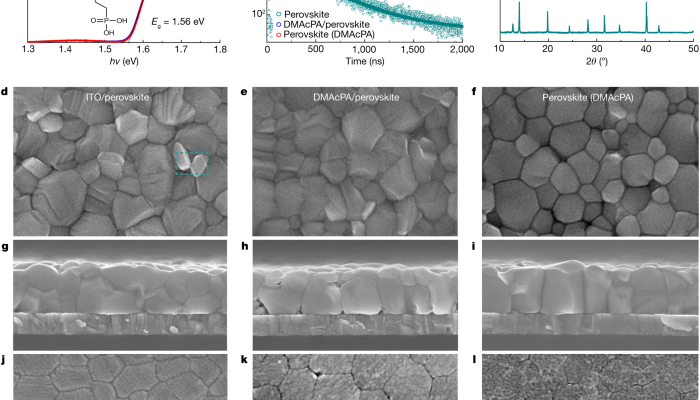

This Nature article (preprint preview) describes a materials and interface engineering strategy that substantially improves inverted tin-based perovskite solar cells (TPSCs). The team introduces a phosphonic-acid-based molecular film placed at the buried interface between the hole transport layer and the tin perovskite. This film creates a homogeneous interfacial layer with energy-level matching and a superwetting underlayer that directs the growth of uniform Sn-perovskite films with fewer defects and lower non-radiative recombination.

The result: small-area inverted TPSCs reach a record power conversion efficiency (PCE) of 17.89% (certified 17.71% by reverse scan) and a record 14.40% on 1 cm2 devices. Encapsulated devices show excellent stability — retaining over 95% of initial PCE after 1,344 hours of ambient shelf storage and over 94% after 1,550 hours under continuous 1-sun illumination. The paper emphasises scalable device fabrication and demonstrates improved hole extraction via optimised buried-interface chemistry.

Key Points

- A phosphonic-acid molecular film at the buried interface improves energy-level alignment and hole extraction in inverted TPSCs.

- The molecular layer forms a superwetting underlayer that guides uniform growth of Sn-perovskite films, reducing defect density.

- Small-area devices achieve a record PCE of 17.89% (certified 17.71% under reverse scan).

- 1 cm2 devices reach a record 14.40% PCE, demonstrating promising scalability of the approach.

- Encapsulated cells retain >95% of initial PCE after 1,344 h shelf storage and >94% after 1,550 h continuous 1-sun operation, indicating strong operational stability.

- The work addresses two persistent TPSC challenges: suboptimal hole-transport/buried interfaces and film quality-related non-radiative losses.

Why should I read this?

Because if you care about lead-free solar tech that actually performs and lasts, this paper is a neat shortcut — they fixed a messy buried interface with a clever molecular film and got industry-grade efficiencies and stability. Short version: better interfaces = better tin perovskites, and that could matter if you’re tracking greener photovoltaics.

Context and relevance

Tin-based perovskites are a leading non-toxic alternative to lead-based devices, with an ideal bandgap that promises high theoretical efficiency. However, practical PCEs and stability have lagged due to interface losses and film defects. This work is significant because it tackles the buried-interface problem directly — a common bottleneck for hole extraction in inverted architectures — and demonstrates both top-line efficiency gains and durability under realistic conditions.

The results are relevant to researchers and R&D teams working on lead-free photovoltaics, interface chemistry, and scalable device fabrication. If scaled and reproduced across manufacturing-relevant processes, the approach could accelerate commercial interest in tin-perovskite modules and reduce reliance on lead-containing absorbers.