Vector-stimuli-responsive magnetorheological fibrous materials

Article Date: 05 November 2025

Article URL: https://www.nature.com/articles/s41586-025-09706-4

Article Image: https://media.springernature.com/lw685/springer-static/image/art%3A10.1038%2Fs41586-025-09706-4/MediaObjects/41586_2025_9706_Fig1_HTML.png

Summary

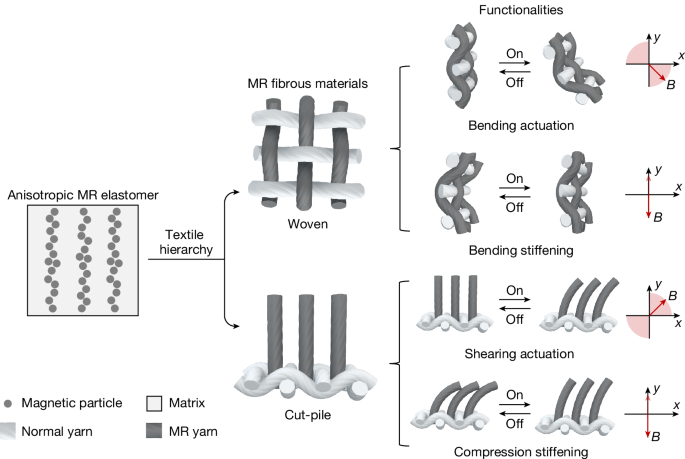

This Nature paper presents a scalable route to magnetorheological (MR) fibrous materials: continuous high-loading MR fibres (57 μm diameter, 70 wt% carbonyl iron particles in LDPE) are melt-spun with in‑situ high-speed drawing, twisted into MR yarns and assembled into woven and cut-pile fabrics. The resulting materials are magnetically anisotropic and show vector-stimuli-responsive behaviour — they bend when the magnetic field is non-parallel to the yarn/fabric axis and stiffen when the field is parallel — enabling both actuation and tunable stiffness in one fibrous material. Key metrics and simple models (χm/E for material choice; Ay/Iy for geometry) guide design. Demonstrations include a fabric linear actuator, active ventilation fabric, a conformable gripper and an untethered haptic finger glove. The authors report km-scale fibre production, fast response times and robust cyclic durability.

Key Points

- Scalable fabrication: melt spinning + high-speed drawing produced continuous MR fibres (57 μm) with 70 wt% carbonyl iron particles and production speeds ≈ 2 km h−1.

- Design metrics: χm/E (material susceptibility vs stiffness) and Ay/Iy (yarn geometry) predict bending and stiffening performance, enabling rational yarn/fabric design.

- Dual-mode vector response: MR yarns/fabrics bend under inclined fields and stiffen under parallel fields; yarns achieve ≈6.5 N m kg−1 moment density and ~30× stiffness tunability up to safe magnetic fields (~300 mT).

- Textile architectures: woven MR fabrics (in-plane bending) and cut-pile MR fabrics (surface shearing and tunable compression modulus) convert yarn actuation to useful macroscale motion and force.

- Practical demos: a 5 mm-stroke fabric linear actuator, active ventilation fabric with controllable breathability, a gentle conformable gripper for delicate items and an untethered haptic finger glove delivering kinaesthetic and tactile feedback.

- Durability and dynamics: fast response (tens to hundreds of ms), preserved actuation after ~10,000 cycles, and minimal creep under load with magnetic stiffening.

Content summary

The authors identify limitations of traditional MR elastomers (stiff matrices, need for strong fields, pre-magnetised hard-magnetic fibres) and propose matrix-free, soft-magnetic MR fibrous materials assembled into textiles as a solution. They selected LDPE as the polymer matrix and SiO2-coated carbonyl iron particles (CIPs) for high susceptibility with low remanence. By optimising rheology and χm/E, they settled on a 70 wt% CIP composite suitable for melt spinning. High-speed drawing aligns polymer chains and orients particles, producing thin, high-loading fibres that are twisted into seven-fibre yarns and heat-set to stabilise geometry.

Analytical models for bending and stiffening of a yarn under magnetic fields are developed and validated experimentally. The yarns display two operation modes: bending (torque from misalignment) and stiffening (magnetic attraction between wrapping fibres increases internal friction). Assembled into woven and cut-pile fabrics, the yarns scale moment output and stiffness and enable distinct functions: in-plane bending/shearing, out-of-plane compression tuning and conversion to linear motion. The paper ends with application demonstrations and a thorough methods section covering materials processing, characterisation and testing protocols.

Context and relevance

This work sits at the intersection of smart materials, soft robotics and wearable technology. It addresses common barriers — low filler load, scale-up, and disordered magnetisation in textiles — with a manufacturable composite-and-textile approach. The combination of high magnetic loading in thin fibres, clear design rules and textile-ready assembly makes the findings highly relevant for developers of soft actuators, adaptive protective clothing, haptic devices and compliant grippers. The use of soft magnetic CIPs avoids pre-magnetisation steps required by hard-magnetic fibres, simplifying integration and reducing inter-fibre interference during actuation.

Author style

Punchy: the paper reads like an engineering playbook — metrics you can use, processes you can replicate, and devices that demonstrate real utility. For anyone building magnetic textiles or fabric-based actuators, the detailed fabrication and characterisation are directly actionable.

Why should I read this?

If you care about smart textiles, soft robotics or haptic wearables, this is proper useful — they show a scalable way to make thin, high-loading magnetic fibres, give simple rules for designing yarns and fabrics, and actually use them in devices that work. Saves you time sifting through incremental lab demos: here’s a practical route you could adapt.