NIST’s ‘Living Reference Material’ Could Accelerate R&D of Lifesaving Biological Drugs

Summary

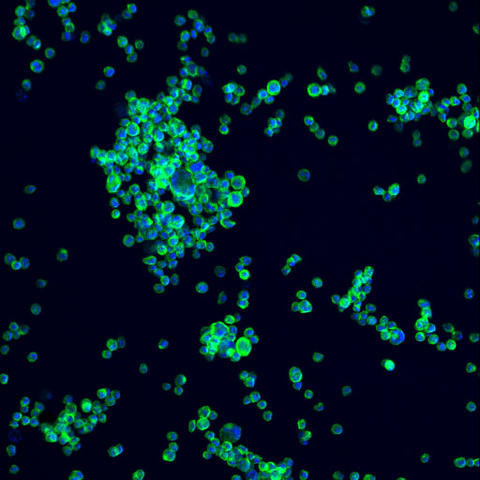

NIST, working with MilliporeSigma and NIIMBL, has released a living reference material called NISTCHO: clonal Chinese hamster ovary (CHO) cells engineered to produce the NIST monoclonal antibody (NISTmAb). Unlike the earlier single-use NISTmAb protein standard, NISTCHO is a renewable biological source (one millilitre contains ~10 million cells) that lets manufacturers, equipment makers and trainers see how cell culture, bioreactor design and downstream processing affect final antibody properties. The RM is formally released as Reference Material 8675 and includes measured controls such as gene-copy ratios to ensure vial-to-vial consistency.

Key Points

- NISTCHO is a living reference material: CHO cells that produce the well-characterised NISTmAb protein.

- Each RM vial contains ~1 ml of suspension with approximately 10 million cells (Reference Material 8675).

- The living RM lets industry test how upstream and downstream process choices change antibody quality — something a finished-protein RM cannot show.

- NIST measured and certifies critical parameters (for example gene-copy ratios) to ensure reproducibility between vials.

- Applications include process development, quality assurance, equipment validation, analytical method benchmarking and workforce training.

- The RM supports an industry sector already worth hundreds of billions of dollars and projected to keep growing rapidly.

Content Summary

Monoclonal antibodies (mAbs) are a major and growing class of therapeutics used across oncology, autoimmune disease and more. Historically, NIST provided a finished-protein standard (NISTmAb) to help labs check their measurement methods. However, because finished proteins cannot reveal how manufacturing steps affect product attributes, NIST and partners developed NISTCHO: a clonal CHO-K1 cell line that continuously produces the NISTmAb variant used in the original standard.

MilliporeSigma performed gene insertion and clone selection to isolate a high-producing, stable cell line. NIST characterised the cells and quantified metrics such as the gene-to-genome ratio so purchasers can rely on consistent behaviour within known uncertainty bounds. The living RM moves from research-grade material (first introduced in 2023) to a full reference material intended for reference measurements, quality assurance and method development.

Context and Relevance

This RM addresses a practical gap in biomanufacturing: understanding how process choices translate into subtle but critical changes to complex biologic drugs. With ~80% of mAb therapeutics produced in CHO cells, a standardised living cell line gives manufacturers and equipment makers a common baseline to optimise bioreactors, media, purification steps and analytical instrumentation. It also helps regulators and labs harmonise measurements and supports training of a skilled workforce — all crucial as the mAb market continues rapid expansion.

Why should I read this?

Short version: if you work in biopharma, medtech, regulatory science or supply-chain equipment for biologics, this matters — big time. NISTCHO is a practical tool that lets you test and improve real manufacturing steps, not just the finished product. We’ve saved you the slog of the paper: this is a concrete, industry-ready standard that will make process development and QA faster, more reproducible and easier to compare across labs.